Additional solutions

Contact us.

Initial, non-binding consultation: Send us a message and we will get back to you promptly.

![[Translate to English:] Wir sind für Sie da! [Translate to English:] Mitarbeiter mit Headset](/fileadmin/z_dummy/Kontakt-556x423.jpg)

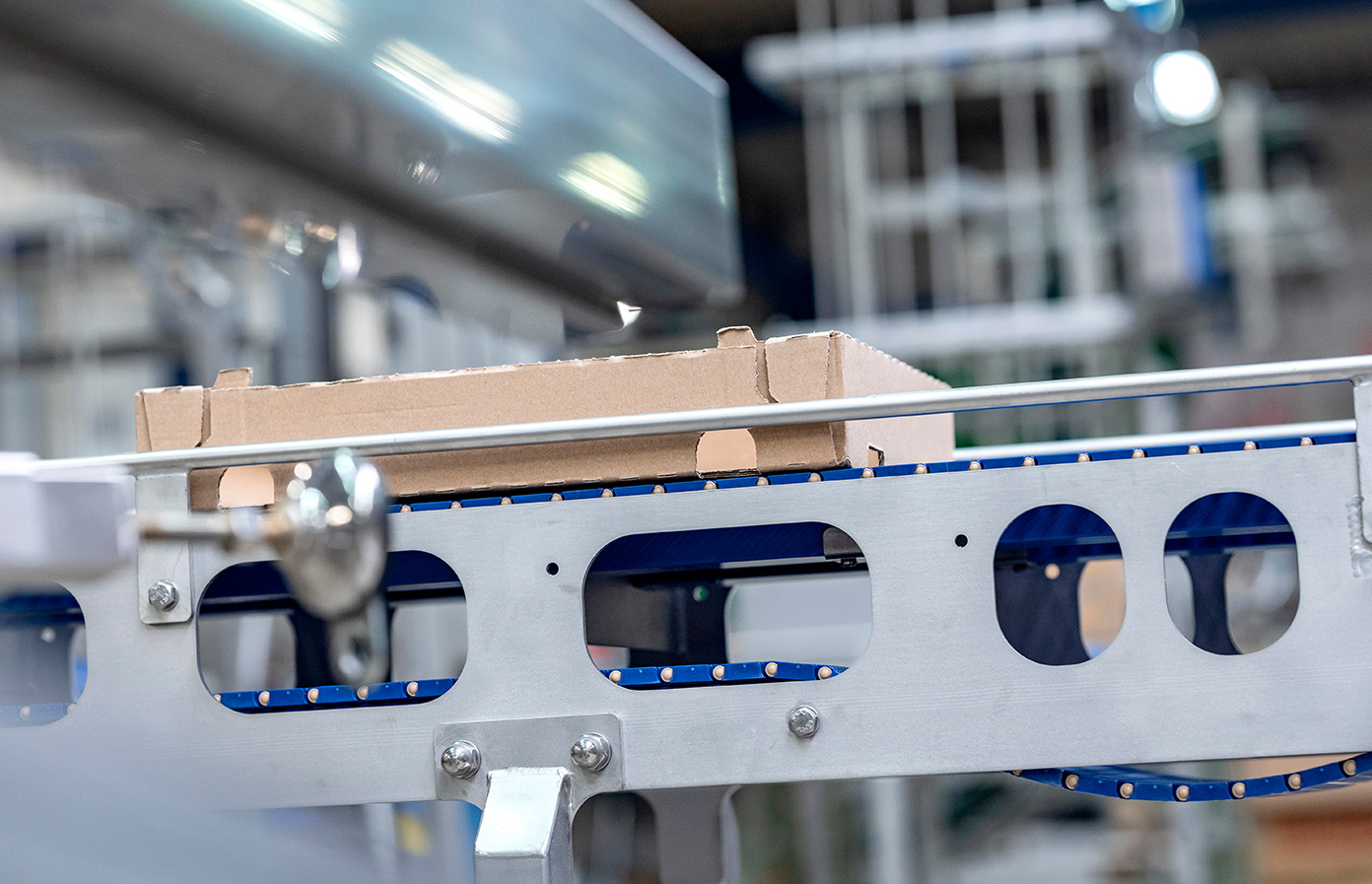

Our modular conveyor systems cover all the key areas of application – transporting, sorting, distributing, stacking, storing and picking – with the utmost precision and effectiveness and even under the toughest spatial conditions where necessary. Our extensive portfolio of partially and fully automated components includes corner transfer conveyors, turners, turntables, lifters, line distributors, pushers, stackers and paternoster lifts.

Whether it’s in container, crate and Euro pallet form or in special sizes, Helmers’ conveyor technology with a highly hygienic design is low-maintenance and works in a process-oriented manner. We dovetail functional areas, special-purpose machines and processes to create perfect intralogistics solutions for an extremely wide variety of materials to be conveyed. Materials to be conveyed.

Initial, non-binding consultation: Send us a message and we will get back to you promptly.

![[Translate to English:] Wir sind für Sie da! [Translate to English:] Mitarbeiter mit Headset](/fileadmin/z_dummy/Kontakt-556x423.jpg)